California’s desert landscape of Coachella Valley will soon be home to a community of 3D printed zero net energy homes. Designed by Mighty Buildings, a construction technology company, in partnership with sustainable real estate group Palari, the entirely 3D-printed neighbourhood will offer smart and sustainability-oriented homes.

“This will be the first on-the-ground actualization of our vision for the future of housing - able to be deployed rapidly, affordably, sustainably, and to augment surrounding communities with a positive dynamic,” said Alexey Dubov, co-founder of Mighty Buildings. In fact, the project comes as California’s housing shortage crisis continues to rage, with estimates of 1.8m to 3.5m new units needed by 2025.

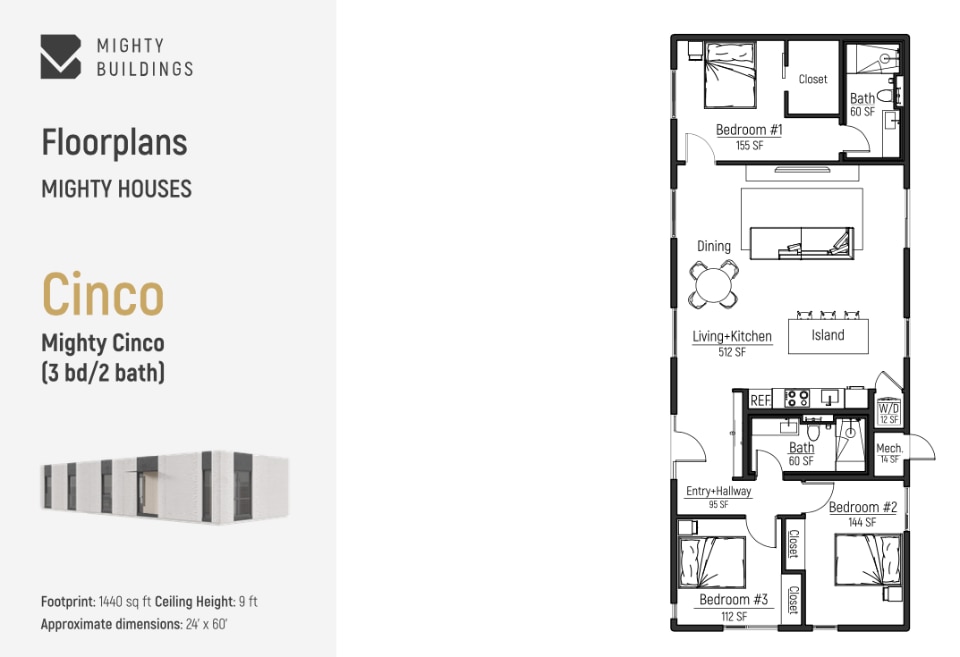

Located in a five acre parcel of land in Rancho Mirage, the 15 eco-friendly homes will complement their natural surrounding with Mid-century modern architecture. Each property will consist of a three-bedroom, two-bath primary residence of 135sqm, along with a secondary residence of two bedrooms and one bath. Prices go from $595,000 for a base 3BR/2BA model, up to $950,000 for a two-home configuration with upgrades.

The company invented a proprietary composite material consisting of a newly developed non-silicate light stone and steel components. Thanks to a UV-curing process, such material hardens almost immediately, while also maintaining cohesion between layers to create a monolithic structure. “This allows us to 3D-print elements like overhangs or ceilings without the need for additional supporting formwork,” a spokesperson for Mighty Buildings explained to Domus. “Additionally, the composite can be post-processed (milling, finishing, etc.) with robotic arms, unlike traditional concrete.”

This means that around 80% of their production process is automated and has the capacity to build a 32sqm house overnight, the company claims. At the same time, it can eliminate 99% more waste than conventional construction. ”We are able to capture the powder from the milling process and incorporate that into new printing material as filler,” the spokesperson commented.

At the units’ end of life, the company is thinking of reusing them as filler or utilizing new advances to convert the material into clean electricity, while exploring nascent opportunities, such as biological degradation using algae or enzymes.

- Project:

- Rancho mirage 3D-printed neighbourhood

- Location:

- Coachella Valley, California

- Architect:

- Mighty Buildings

- Surface:

- 5 acres