The iconic white Starbucks cup is getting a sustainable upgrade. The company has introduced a revamped version of its classic single-use cup for hot beverages. While the design remains instantly recognizable to millions of customers, the material has changed: the new cup is certified home compostable and widely recyclable—without compromising the customer experience or making baristas’ jobs more complicated.

One of the main issues with traditional coffee cups is the plastic lining inside, which makes it difficult for most waste processing plants to separate the paper from the plastic—requiring specialized technology. Starbucks’ new solution addresses this: both the cup and lid can now be thrown into recycling bins or composted at home, leaving no harmful residue for people or the environment.

“The new hot cup from Starbucks in Europe provides a widely recyclable and home-compostable alternative for customers who don’t have a reusable cup. I’m incredibly proud of the team behind this innovative solution and excited to see it in the hands of our customers across Europe as they enjoy their coffee. We’re eager to learn from this rollout and continue focusing on sustainable innovations that meet the evolving needs of markets around the world,” says Duncan Moir, President of Starbucks EMEA. On the same topic, Vincent Mooij, Director of Circpack—the Veolia Group’s specialist packaging consultancy and certification division—adds: “This innovation is a real step forward in reducing plastic waste while improving material recovery.”

The collaboration between Starbucks and Transcend was key to achieving this breakthrough. Over the course of more than three years, the two teams worked together to test multiple prototypes, putting them through thousands of hours of technical trials. The result is not only a perfected cup design, but also the development of new, large-scale manufacturing capabilities. The new cup is produced at Transcend’s facility in Ystrad Mynach, Wales, and made from traceable wood fibers sourced from Northern European forests. It’s coated with a mineral-based material developed in Brescia, Italy.

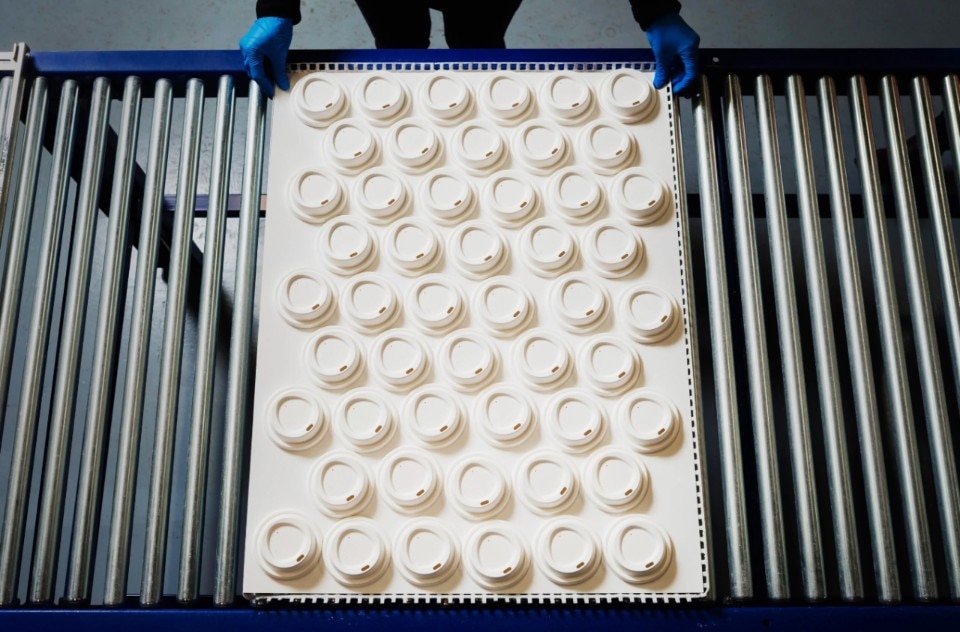

Thanks to extensive research and Italian technology, the traditional plastic lining has been replaced with a patented silica-based mineral coating called Qwarzo. This same material is used on the lid, now made from recyclable cellulose fiber instead of conventional plastic. The new lid is designed to be sturdy and stable, maintaining its shape even when in contact with hot liquids.

The cup is already available in Spain and Hungary, with rollouts planned this month in other European countries including Italy, Germany, France, Sweden, Switzerland, and Austria. It is expected to launch in the UK and Ireland by the end of the year.