Every industry deals transversely with sustainable development, with a focus on production cycles, raw materials and, last but not least, logistics. The debate on the environmental issue is complicated, but certainly open. Now more than ever, it is an issue that the world of furniture and design companies are facing. Giovanni Maggioni, CEO of Protek, a Lecco-based company which has been producing subframes and sliding window and door systems since 2001, told us about his experience.

Sustainability has significantly entered the programme of design companies and not only, becoming a priority. What actions have you implemented?

For several years now, we have been pursuing a path of greater environmental awareness. For instance, our production centre: it was built eight years ago with energy class A++, a building designed when the environmental issue was less urgent than it is today. We made this economic effort by developing a heating and cooling geothermal system, with quadruple-glazed windows to insulate the building and maximise energy performance. The environmental issue goes hand in hand with that of being made in Italy, and Protek products are one hundred per cent so: all the components are purchased from neighbouring companies. At a time when logistics are difficult, sourcing exclusively from suppliers close to the company has paid off, even though it is certainly more expensive from an economic point of view.

Is technology an ally of yours in this process?

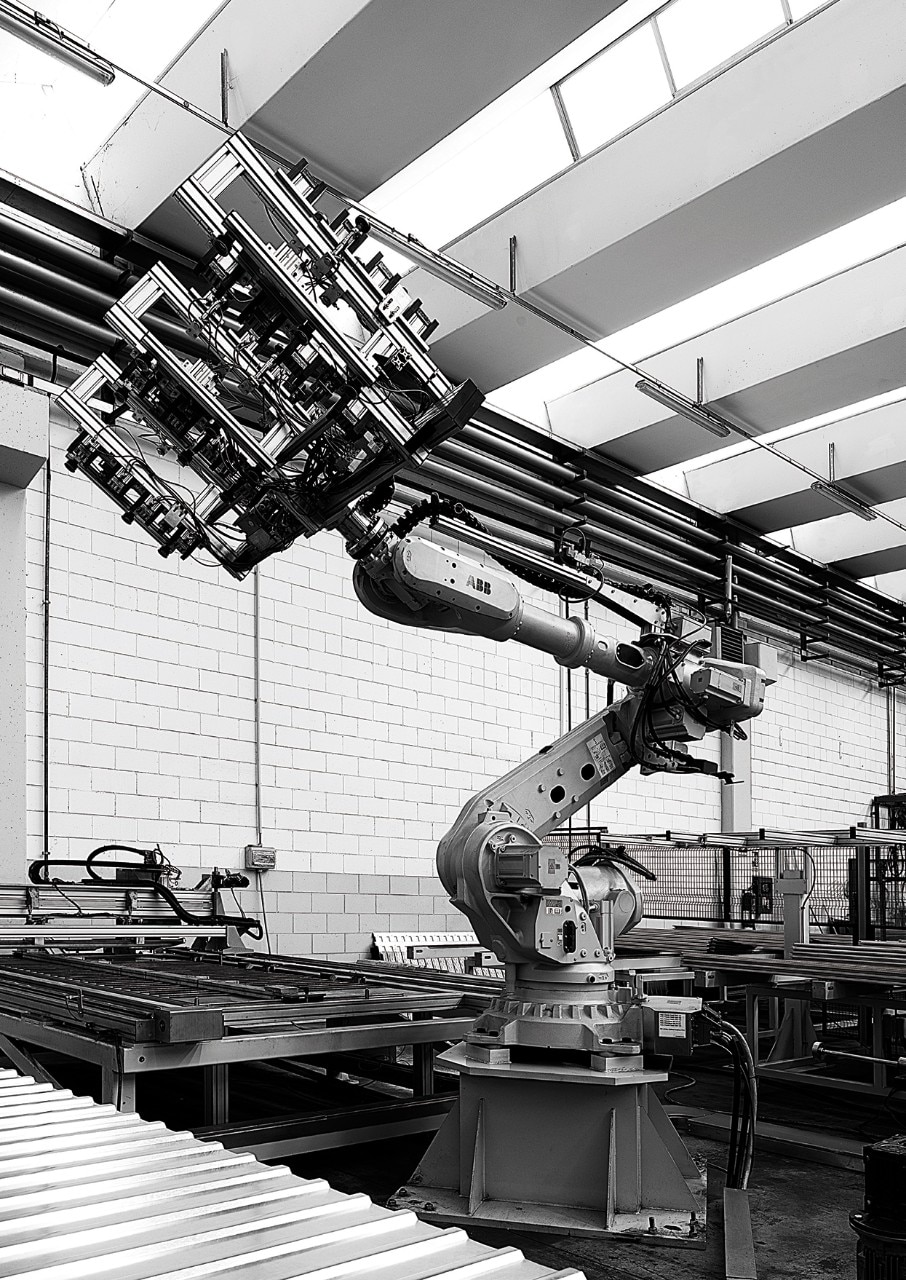

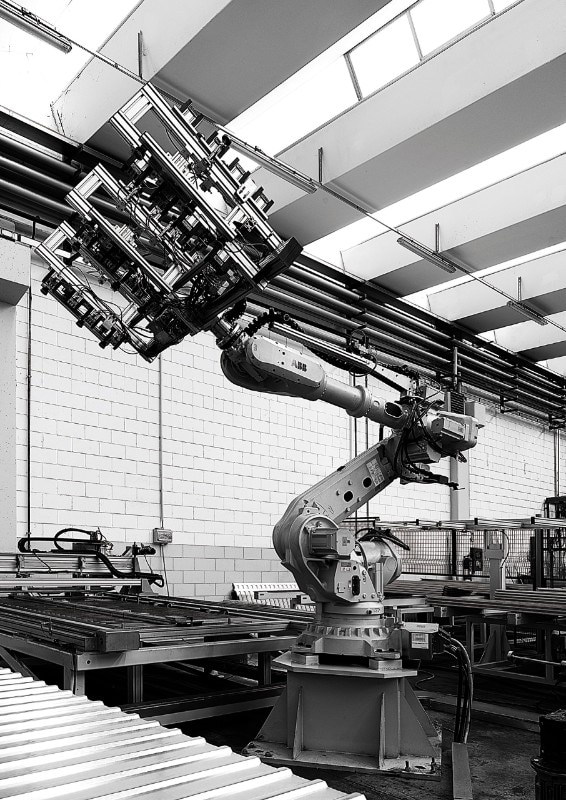

We are completing a new 4.0 system, which will be used to produce the new range of elements we have redesigned. It will be innovative, flexible and fast production. Speaking of technology, we are also considering the possibility of a fully automated storage facility.

What are you doing in terms of products?

The wooden parts of our frames have been FSC and PEFC certified for several years now. At the moment we are making an extra effort to redesign all the subframes, trying to eliminate the wooden part. We are also trying to reduce the use of plastics as much as possible in favour of other materials such as aluminium, a material that is easily reusable. I say easily because in terms of energy it is easy to melt it down and use it in other products, thanks to its low melting point. Then there is the installation, which has an impact on the cost of the product: our idea is to help as much as possible all the professionals who will follow this aspect.

What are the most obvious changes in terms of aesthetics and function?

The redesign involves both the standard subframe, finished with wooden details, and the flush-to-wall subframe without jambs. First of all, we eliminated all the environmentally unfriendly parts and revised the product so as to multiply the aesthetic finishing solutions. As we were saying, we made great use of aluminium, a material that allows numerous colour solutions and guarantees high performance.

Speaking of aluminium, how do you plan to deal with the current shortage of raw materials?

It is certainly an unsettling and destabilising issue, which caught entrepreneurs a little by surprise precisely because of the lack of precedent. In this particularly complicated context, the cost of aluminium has practically doubled. With Protek, we got busy by working closely with our historical suppliers and opted for an over-supply purchasing programme that required a financial effort. At the same time the big challenge, from a business point of view, is to maintain a balance in supply in order to avoid stocks of materials that lose value.