In Audi’s showroom in Berlin Zieta Prozessdesign presented his new mirrors collection named Tafla.

Zieta Prozessdesign: Tafla

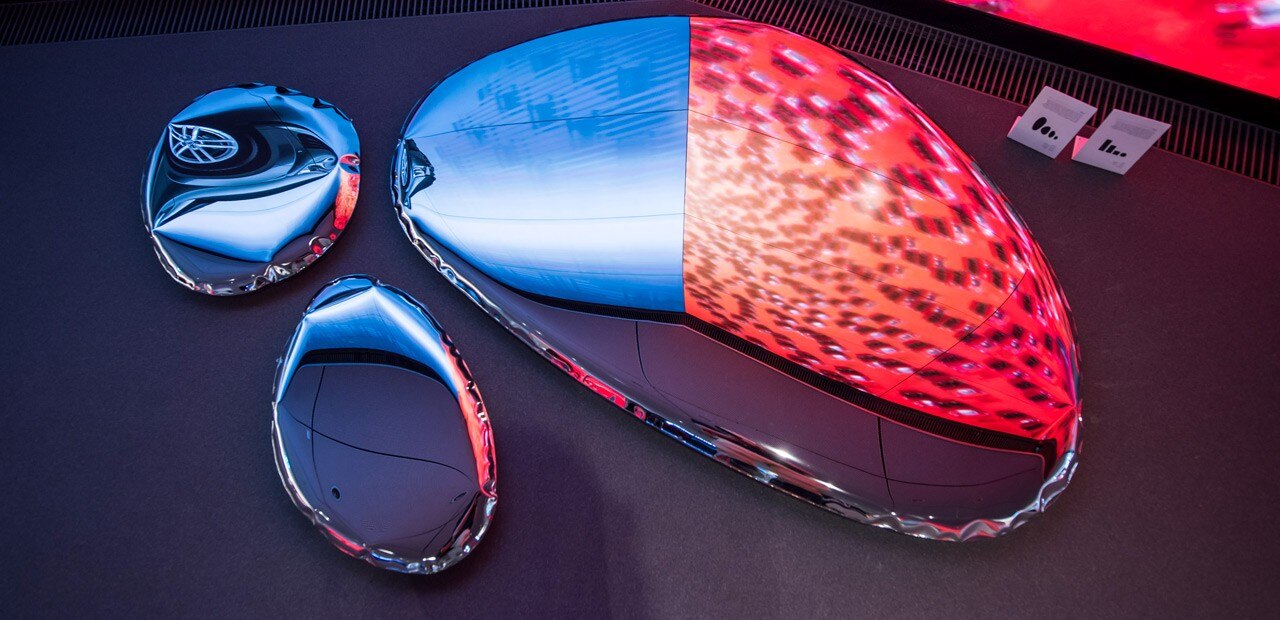

Zieta Prozessdesign joined Audi’s showroom in Berlin to present its new collection of steel mirrors Tafla, made in FiDU technology and characterized by untypical forms.

View Article details

- 27 October 2014

- Berlin

Innovative FiDU technology allows gain unique forms. Ordinary mirror is made of glass or crystal and it is flat. Zieta’s mirrors are made of high-gloss polished metal.

Apart from unusual materials, Tafla is characterized by original, untypical forms. The collection consists of several solids, which although have different shapes perfectly match together. One of them are geometric, simple, symmetric, other are unique, outsized.

FiDU stands for Freie Innen Druck Umformung, “Internal Pressure Forming”, which implies inflating two steel sheets welded around their edges into a 3d object. It takes only two thin steel sheets to create a complicated and very durable 3d object from steel in FiDU. FiDU allows to create customized, individualized bionic shapes and fully recyclable objects using very efficient mass production processes and individualized shaping methods. It is the most flexible tool-less metal forming way ever.

Tafla

Design: Oskar Zieta

Production: Zieta Prozessdesign