Knowledge and awareness of the material and production processes, informed use and efforts to reduce waste and energy consumption are some of the essential aspects of future stone design projects seen in terms of a creative process promoting stone through a modern image.

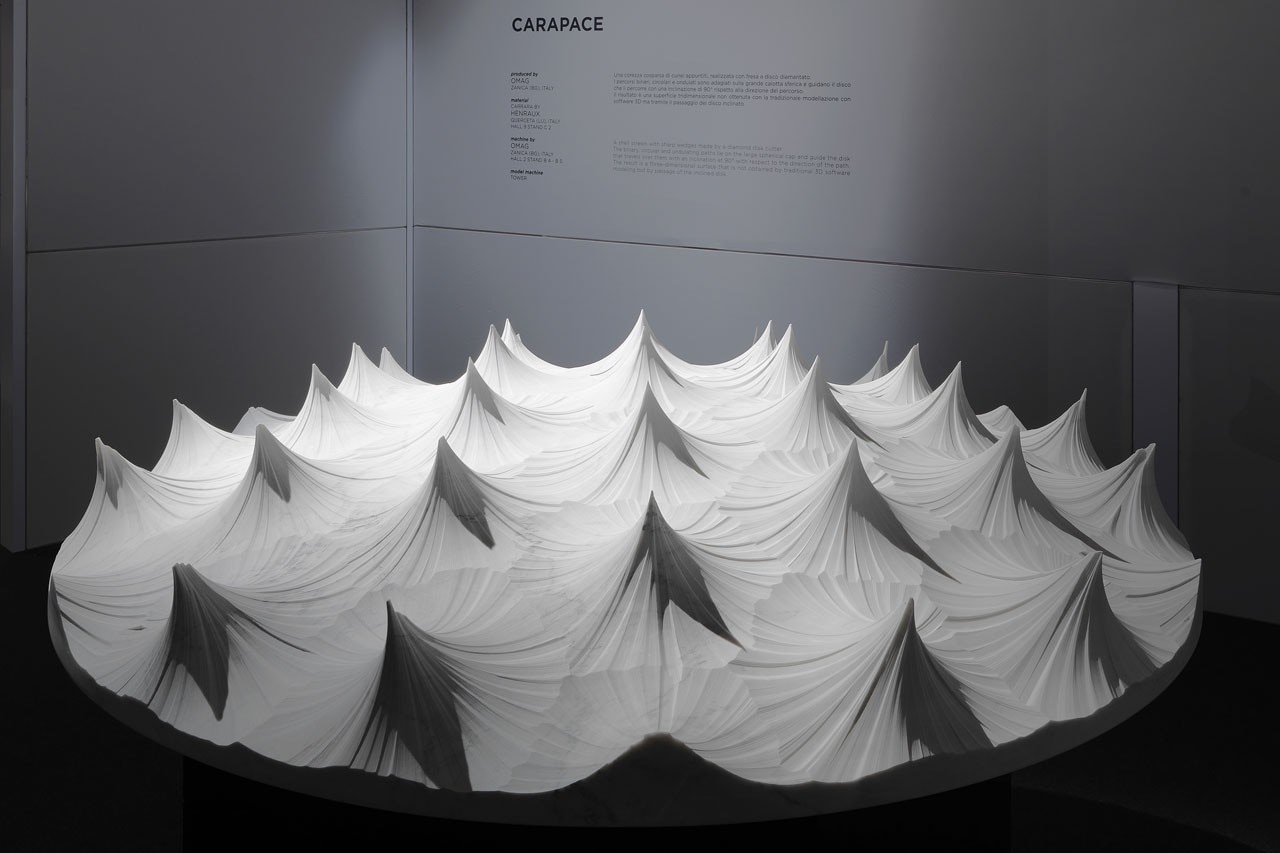

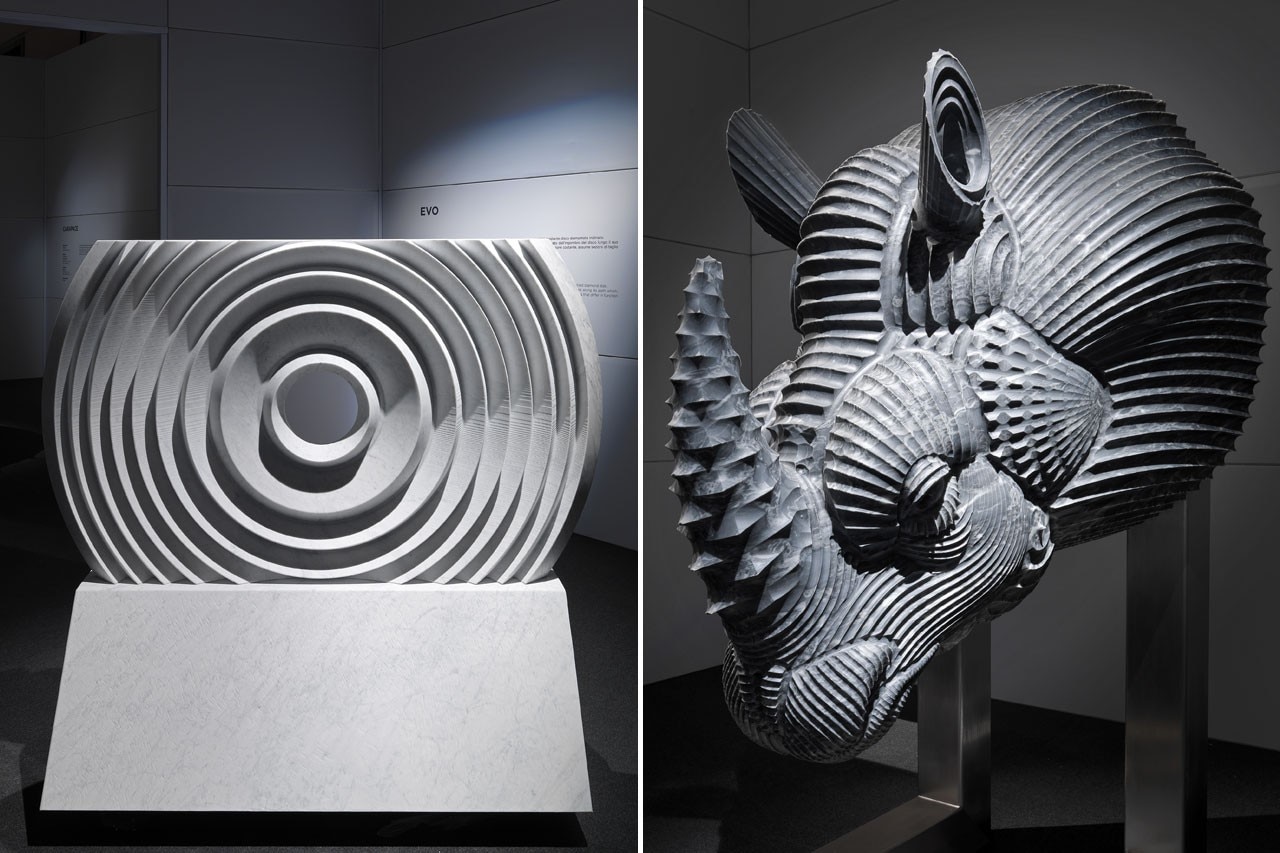

The event tackles several specific technical and processing aspects (5-axis bridge saws with tool, diamond disc, lathe, robot, water jet, etc.) through a preview display of experimental works specifically developed by designer and curator Raffaello Galiotto for leading Italian companies in the sector.

The ancient engraving by Albrecht Durer in 1515 inspired Rhinoceros. Just as the manual straight, curved or geometric hatches delineate the two-dimensional figure so does the cutter sculpt the mass and draw the surface. The graphic texture is first digital, using software, and then material by passage of the cutting tool. It becomes the characteristic feature of the work itself, entirely “machine-made”.

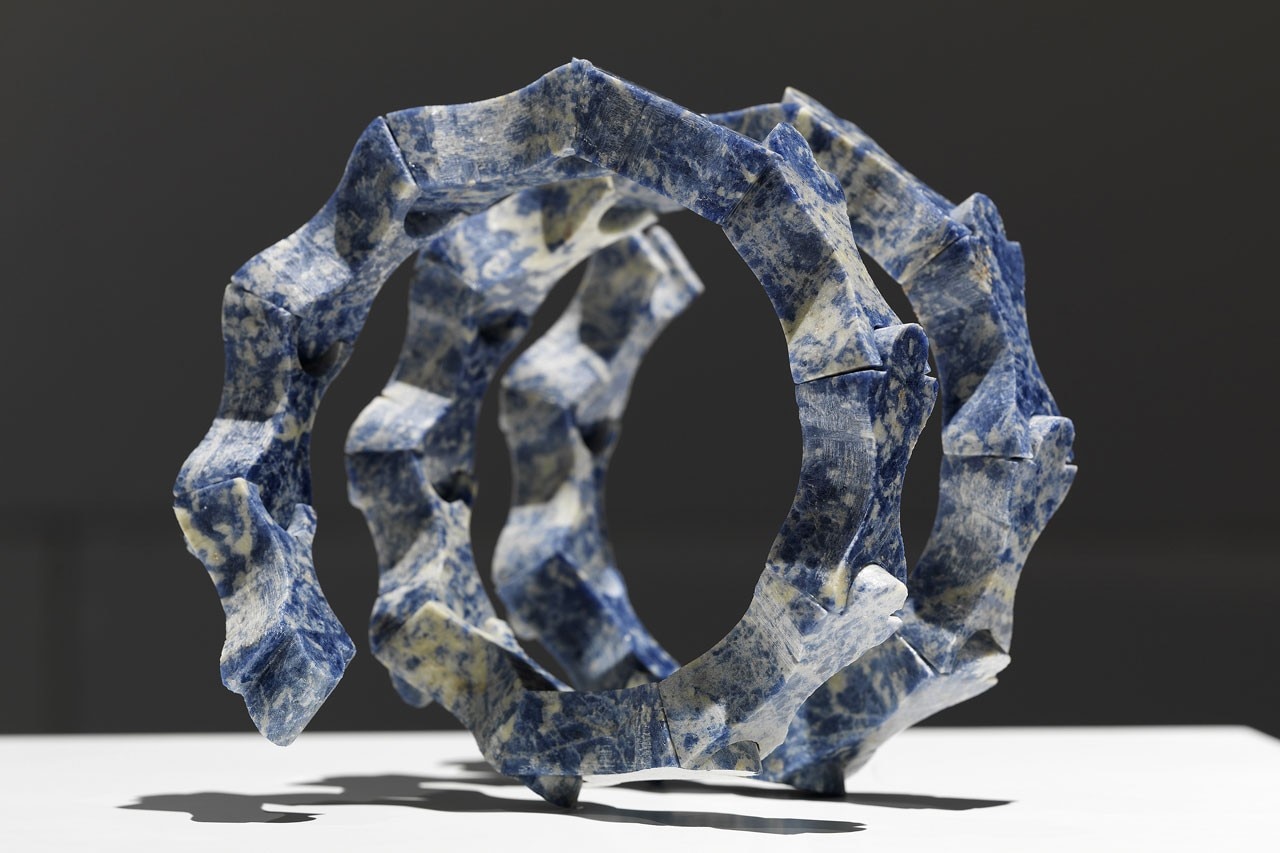

Catenata, Corallo, Corona, Madrepora, Porifera, Serpentina are small marble objects made exclusively using 3D waterjet abrasive cutting technology.

The particularity of these works lies in the complexity of their forms, obtained by following appropriate computer created cutting paths. The machine, thanks to these inclined, incident, multiple and overlapping cuts, is able to produce unexpected curved and perforated three-dimensional solids. Each of these small works investigates and expresses a different geometric problem that is inextricably linked to the specific technology of waterjet cutting.

24 – 27 September 2014

Design and Technology

curated by Raffaello Galiotto

Marmomacc 2014

Verona