The process involves heating a plastic sheet until soft and then draping it over a mould. A vacuum is applied sucking the sheet into the mould. The sheet is then ejected from the mould.

Unlike other thermoplastic forming processes, where powder or resin are the starting point, vacuum forming uses extruded plastic sheet. With vacuum forming a secondary process may be required to trim the formed sheet to arrive at the finished part. The trimmed waste can then be re-ground and recycled.

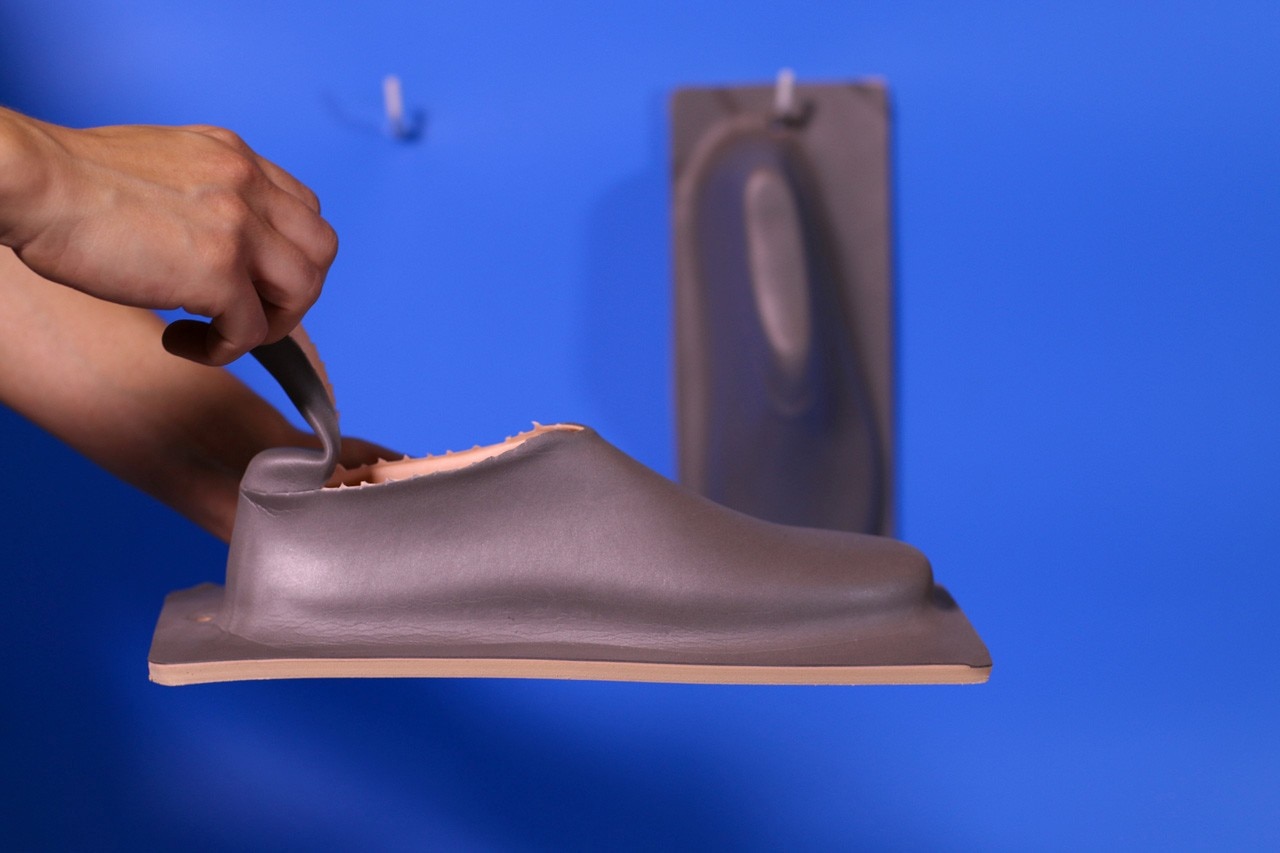

Vacuum Forming Shoe

Design: Lou Moria

A house turns its back on the road to open up to the landscape

The single-family house project designed by Elena Gianesini engages in a dialogue with the Vicenza landscape, combining tranquility and contemporary style through essential geometries and the Mazzonetto metal roofing.