This article originally appeared in Domus 737, April 1992.

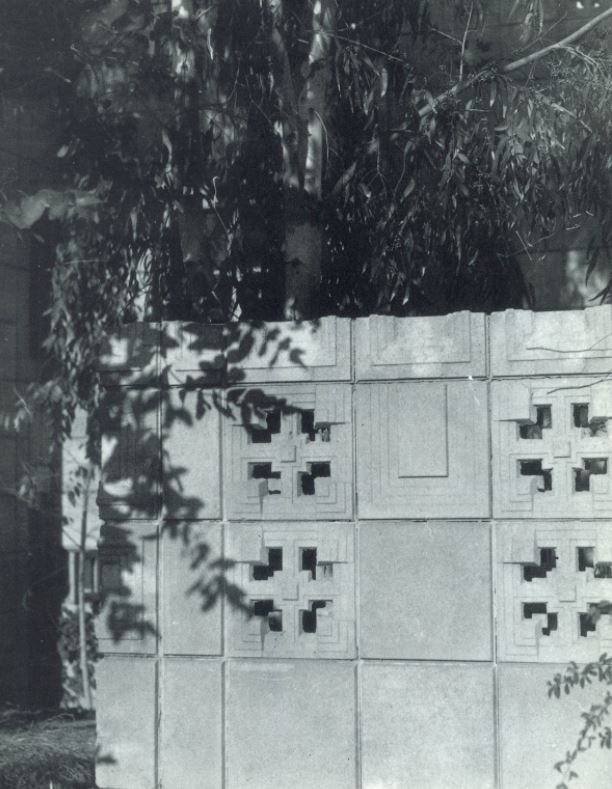

“The concrete block? The cheapest (and ugliest) thing in the building world. It lived mostly in the architectural gutter as an imitation of ‘rock face’ stone. Why not see what could be done with that gutter-rat? Steel wedded to it cast inside the joints and the block itself brought into some broad, practical scheme of general treatment then why would it not be fit for a phase of modern architecture? It might be permanent, noble, beautiful. It would be cheap.

All that imagination needed to make such a scheme feasible was a plastic medium where steel would enter inert mass as a tensile strength. Concrete was the inert mass and would take compression. Concrete is a plastic material – susceptible to the impress of imagination.

We would take that despised outcast of the building industry – the concrete block – out from underfoot or from the gutter – find a hitherto unsuspected soul in it – make it live as a thing of beauty – textured like the trees. Yes, the building would be made of the ‘blocks’ as a kind of tree itself standing at home among the other trees in its own native land”.

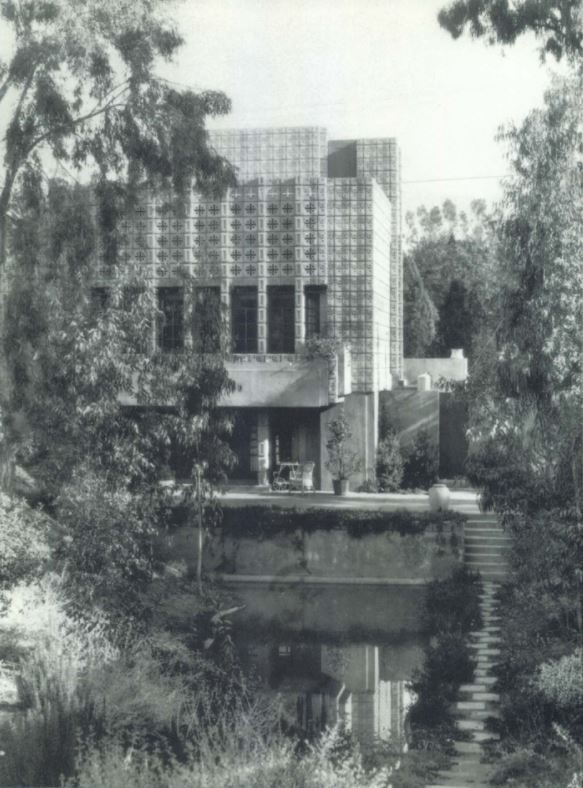

This was what Frank Lloyd Wright wrote in his autobiography when he described the house he built for Alice Millard in Pasadena, California (1923). He was delighted to go to work for Mrs. Millard, the second time. It always pleased him when a client came to him for a repeat performance (there were many who did throughout his career).

“The Millards had lived in a dwelling I had built for them fifteen years ago at Highland Park near Chicago. I was proud to have a client survive the first house and ask me to build a second.

Gratefully I determined she should have the best in my portfolio. That meant, to begin with, something that belonged to the ground on which it stood. Gradually I unfolded the scheme of the textile block-slab house gradually forming in my mind since I got home from Japan. She wasn’t frightened by the idea”.

With her enthusiasm to subscribe to a totally new idea in building methods, and to support her architect in this innovative approach to the concrete block, Mrs. Millard sought a piece of property in Pasadena.

“We saw a charming little ravine, with water in the bottom of it. On each side were two lots for sale, and the ravine didn’t seem to have any particular use. So instead of buying an expensive lot on either side, we bought the ravine, which they were glad to get rid of. They didn’t imagine anybody was going to build on it, but we did”.

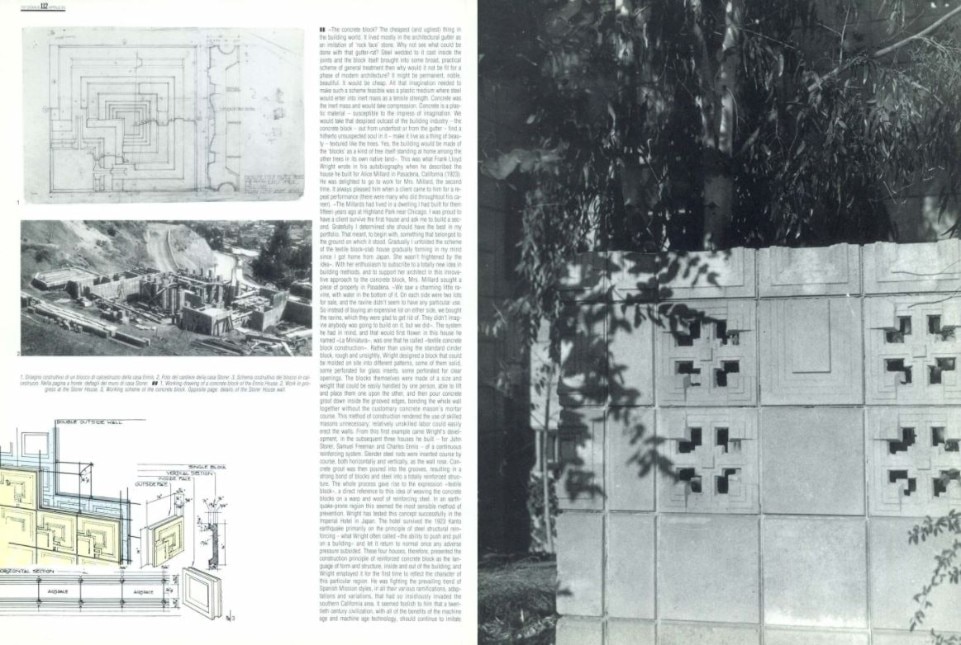

The system he had in mind, and that would first flower in this house he named “La Miniatura”, was one that he called “textile concrete block construction”.

Rather than using the standard cinder block, rough and unsightly, Wright designed a block that could be molded on site into different patterns, some of them solid, some perforated for glass inserts, some perforated for clear openings. The blocks themselves were made of a size and weight that could be easily handled by one person, able to lift and place them one upon the other, and then pour concrete grout down inside the grooved edges, bonding the whole wall together without the customary concrete mason’s mortar course. This method of construction rendered the use of skilled masons unnecessary; relatively unskilled labor could easily erect the walls.

From this first example came Wright’s development, in the subsequent three houses he built – for John Storer, Samuel Freeman and Charles Ennis – of a continuous reinforcing system.

Slender steel rods were inserted course by course, both horizontally and vertically, as the wall rose. Concrete grout was then poured into the grooves, resulting in a strong bond of blocks and steel into a totally reinforced structure. The whole process gave rise to the expression “textile block”, a direct reference to this idea of weaving the concrete blocks on a warp and woof of reinforcing steel.

We would take that despised outcast of the building industry – the concrete block – out from underfoot or from the gutter – find a hitherto unsuspected soul in it.

In an earthquake-prone region this seemed the most sensible method of prevention. Wright has tested this concept successfully in the Imperial Hotel in Japan. The hotel survived the 1923 Kanto earthquake primarily on the principle of steel structural reinforcing – what Wright often called “the ability to push and pull on a building” and let it return to normal once any adverse pressure subsided.

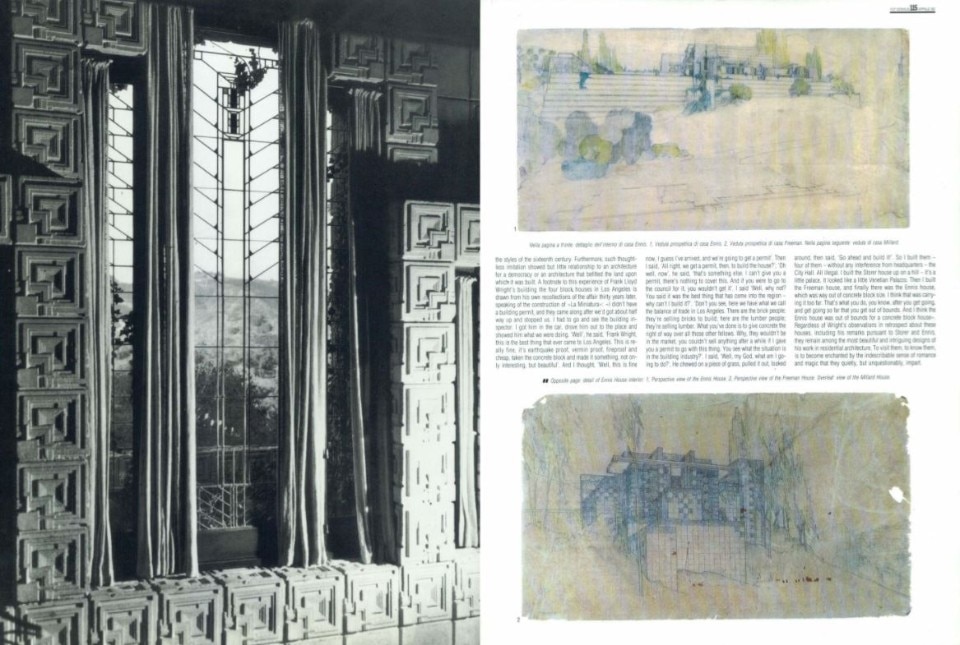

These four houses, therefore, presented the construction principle of reinforced concrete block as the language of form and structure, inside and out of the building; and Wright employed it for the first time to reflect the character of this particular region. He was fighting the prevailing trend of Spanish Mission styles, in all their various ramifications, adaptations and variations, that had so insidiously invaded the southern California area. It seemed foolish to him that a twentieth century civilization, with all the benefits of the machine age and machine age technology, should continue to imitate the styles of the sixteenth century. Furthermore, such thoughtless imitation showed but little relationship to an architecture for a democracy or an architecture that befitted the land upon which it was built.

A footnote to this experience of Frank Lloyd Wright’s building the four block, houses in Los Angeles is drawn from his own recollections of the affair thirty years later, speaking of the construction of “La Miniatura”: “I didn’t have a building permit, and they came along after we’d got about half way up and stopped us. I had to go and see the building inspector. I got him in the car, drove him out to the place and showed him what we were doing. “Well”, he said, “Frank Wright, this is the best thing that ever came to Los Angeles. This is really fine, it’s earthquake proof, vermin proof, fireproof and cheap, taken the concrete block and made it something, not only interesting, but beautiful”.

And I thought, “Well, this is fine now, I guess I’ve arrived, and we’re going to get a permit”. Then I said, “All right, we get a permit, then, to build the house?”; “Oh well, now”, he said, “that’s something else. I can’t give you a permit, there’s nothing to cover this. And if you were to go to the council for it, you wouldn’t get it”. I said “Well, why not? You said it was the best thing that has come into the region – why can’t I build it?”.

“Don’t you see, here we have what we call the balance of trade in Los Angeles. There are the brick people; they’re selling bricks to build; here are the lumber people; they’re selling lumber. What you’ve done is to give concrete the right of way over all those other fellows. Why, they wouldn’t be in the market, you couldn’t sell anything after a while if I gave you a permit to go with this thing. You see what the situation is in the building industry?”.

Concrete is a plastic material – susceptible to the impress of imagination.

I said, “Well, my God, what am I going to do?”. He chewed on a piece of grass, pulled it out, looked around, then said, “Go ahead and build it!”. So I built them – four of them – without any interference from headquarters – the City Hall. All illegal. I built the Storer house up on a hill – it’s a little palace. It looked like a little Venetian Palazzo. Then I built the Freeman house, and finally there was the Ennis house, which was way out of concrete block size. I think that was carrying it too far. That’s what you do, you know, after you get going, and get going so far that you get out of bounds. And I think the Ennis house was out of bounds for a concrete block house”.

Regardless of Wright’s observations in retrospect about these houses, including his remarks pursuant to Storer and Ennis, they remain among the most beautiful and intriguing designs of his work in residential architecture. To visit them, to know them, is to become enchanted by the indescribable sense of romance and magic that they quietly, but unquestionably, impart.

Bruce Brooks Pfeiffer was born in 1930 in South Natick, Massachusetts, and began studying as an apprentice under Frank Lloyd Wright in 1949. In the 1950s he attended an art school in Paris, then returned to Wright's fold. He became director of the Wright Foundation’s archives in 1959 and later served as vice president and trustee of the group.

Opening image: Work in progress at the Storer house. Domus n. 737 archive, April 1992