It is hard to think of an object which is more representative of 2020 than the mask. From a sliver of imagination that used to come straight from the streets and subways of South-East Asia or a device that can be linked to a few, particular professions, it has become an object of mass consumption; infiltrating with arrogance into our everyday horizon, the mask has also led to a spillover event: in shapes, in materials, in the different possible solutions as a personal protective device.

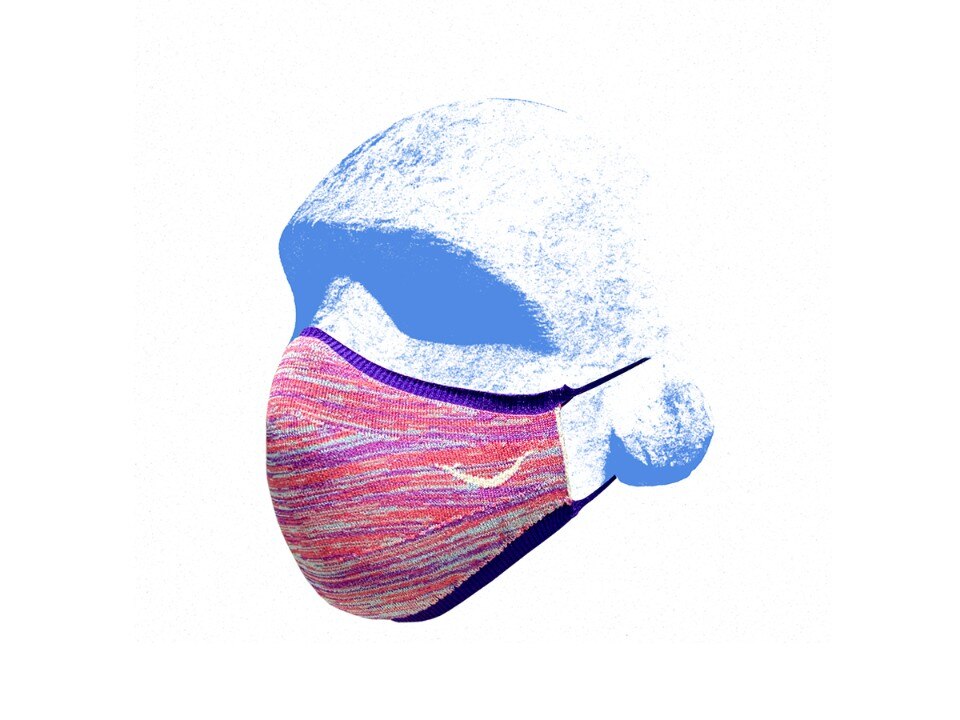

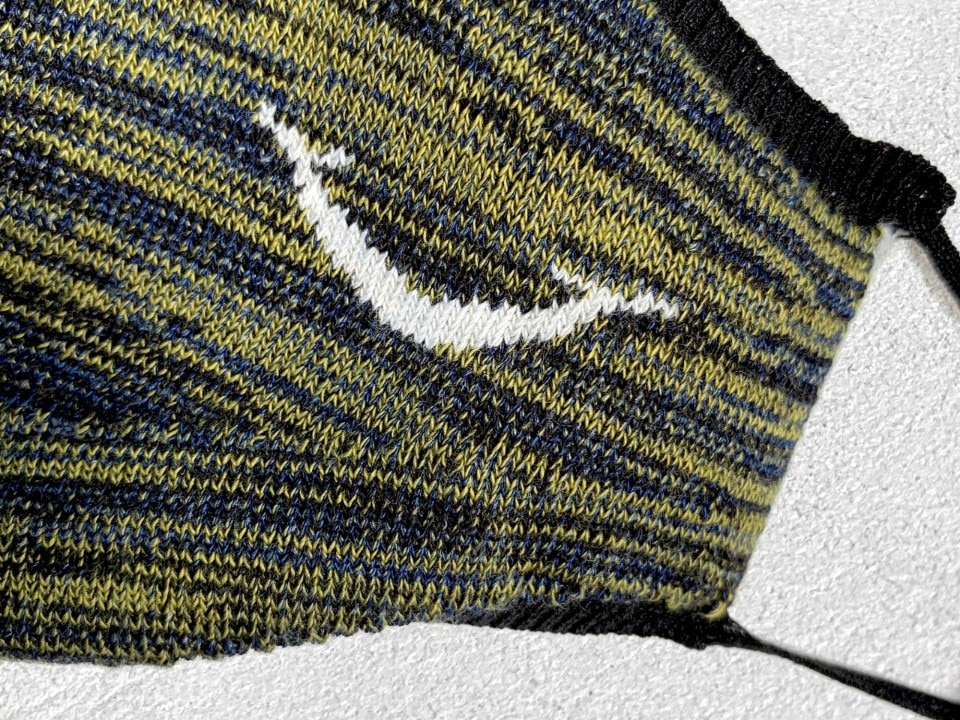

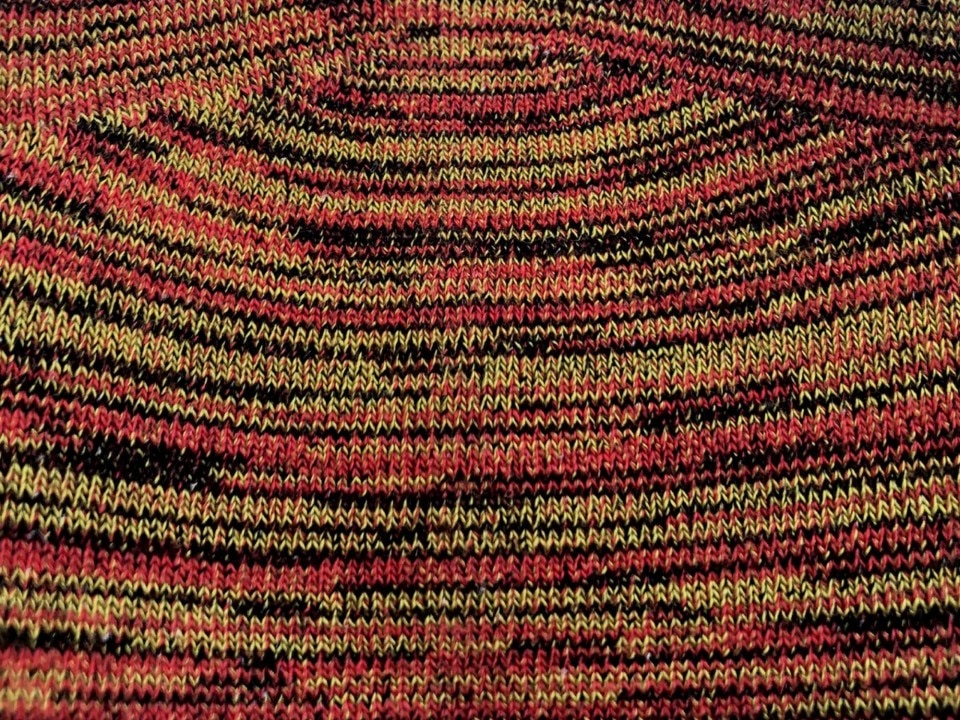

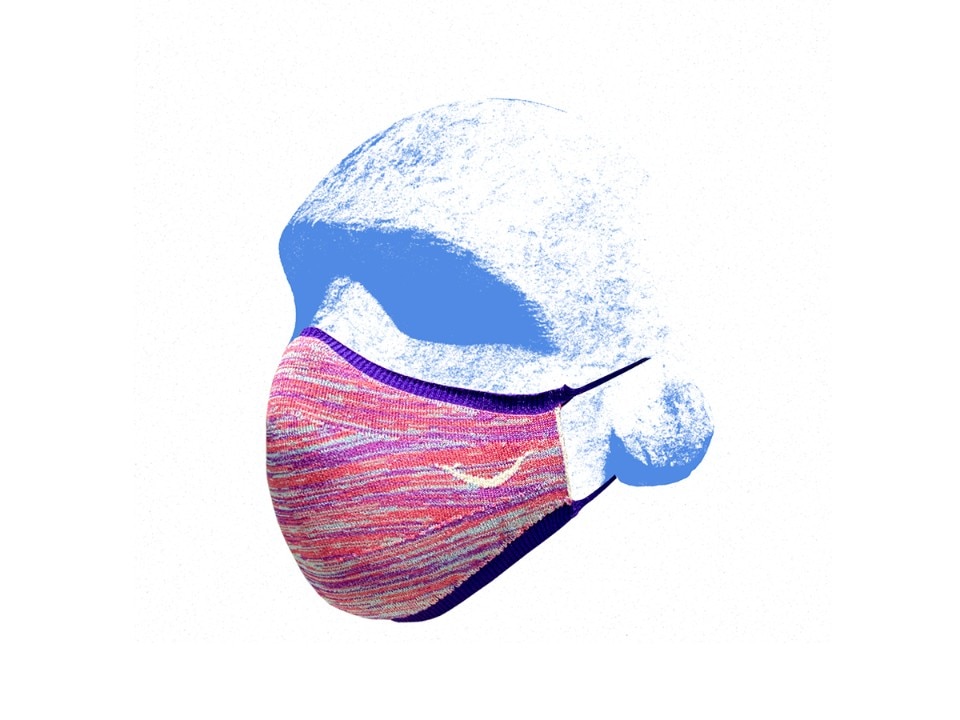

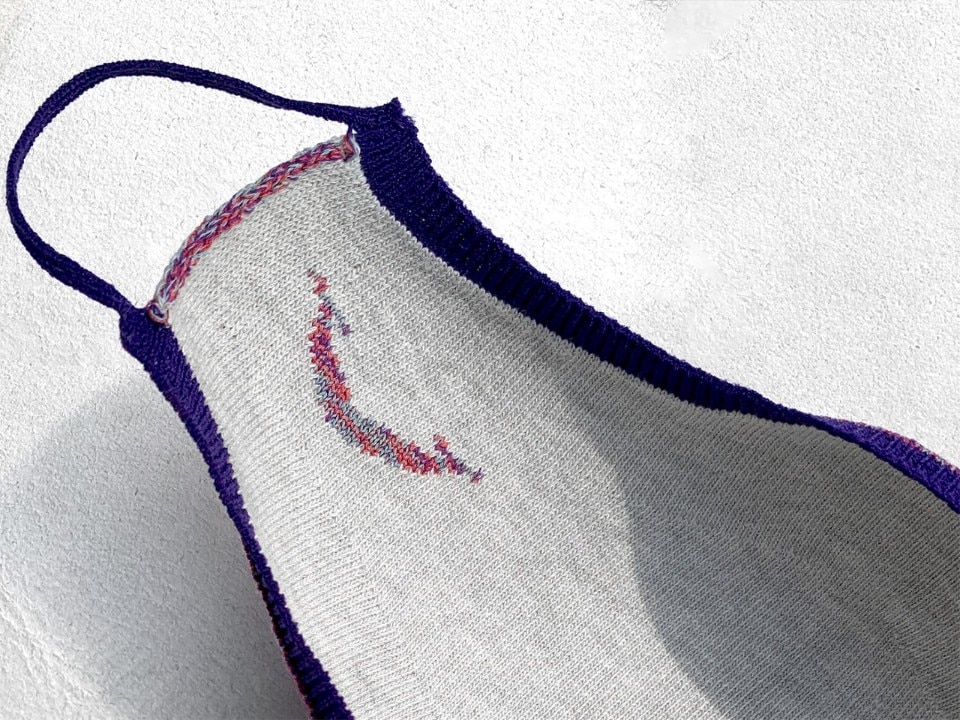

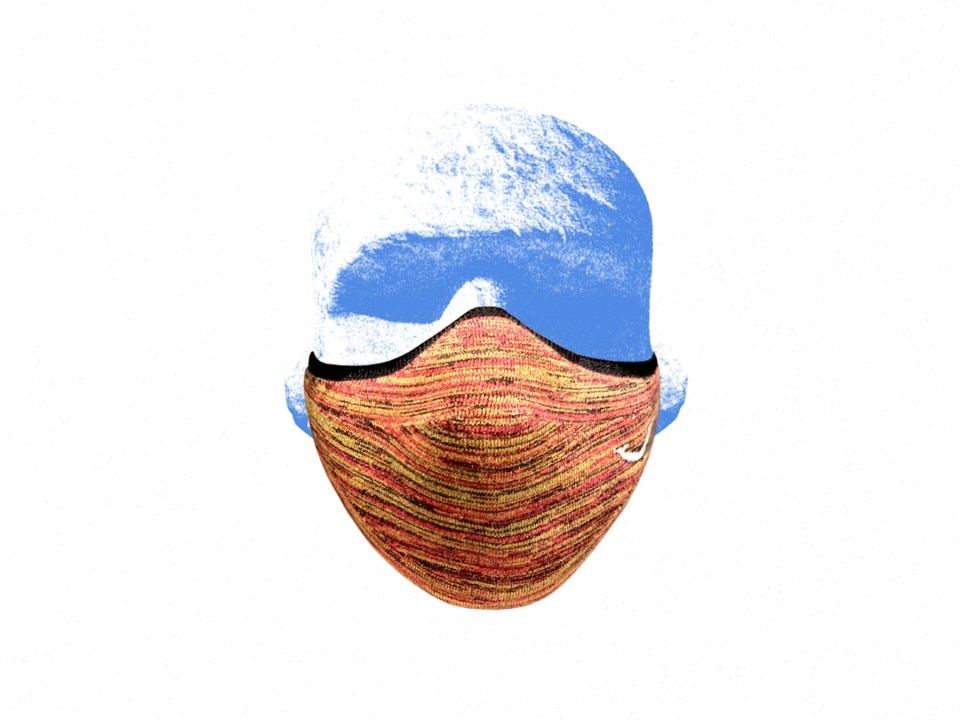

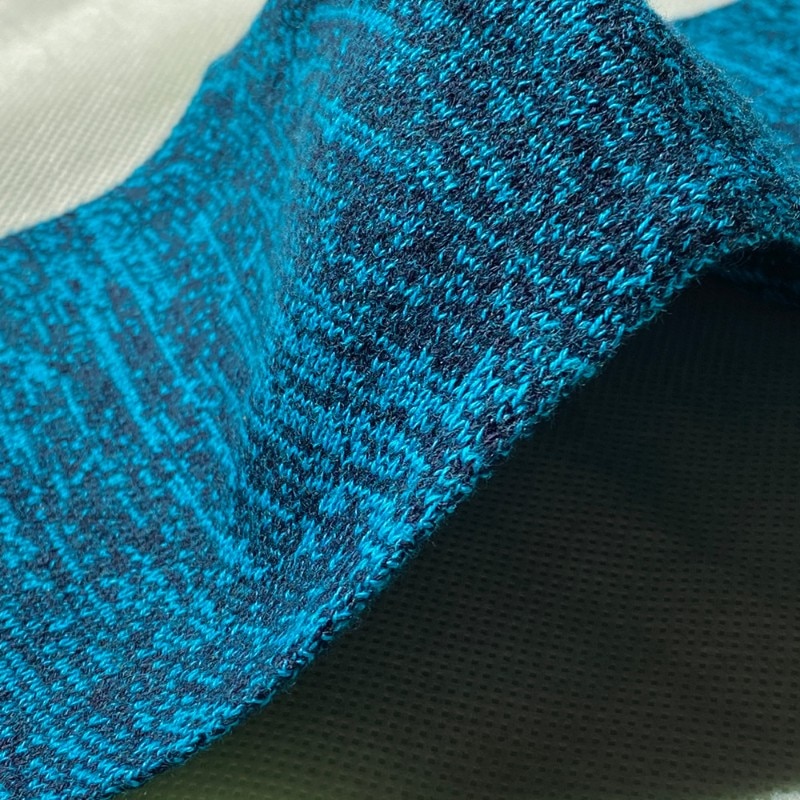

“The masks will become part of our clothing”, say Giulia Bortoli and Mauro Simionato, creators of the Reimiro masks (IG: @reimiro_knitwear), colorful and double layer. Their interior is made of silver/cotton blended yarn to maximize protection against bacterial and viral threats, and the outside is in cotton obtained from the leftovers of textile factories in the Vicenza area in the Veneto area of Italy. These masks are first of all beautiful, and unique. Giulia and Mauro founded Vitelli Maglieria Italiana four years ago, a project that focuses on “sustainable knitwear, small family-run knitting factories and workshops of Vicenza and on local craftsmanship with minimal environmental impact“; this February, the first “homemade” Vitelli fashion show for Milan Fashion Week was held behind closed doors, just after the decree forbidding public events arrived. It was the beginning of the lockdown and the story of these masks, somehow, starts from there. “Reimiro was born right in front of the gigantic, tragic waste theme that would have soon broken out, with forecasts of consumption amounting to 40 million disposable products being used every day“, hence the idea of a brand of sustainable, washable and reusable knitwear items: “we started with product development, laboratory testing, branding and setting-up of an e-commerce, all of this during quarantine and within a few weeks”. Leaning on small companies in the province of Vicenza has made the production process more agile. The first two models of Reimiro masks are marketed as civil protection provisions, without certification. The intention to add a certified mask to the current lineup remains. “It is not easy to find the right balance between breathability and filtration”, explains Giulia Bortoli: “we are working on a third model, but the road ahead is still long”. And the gloves may arrive soon, too.

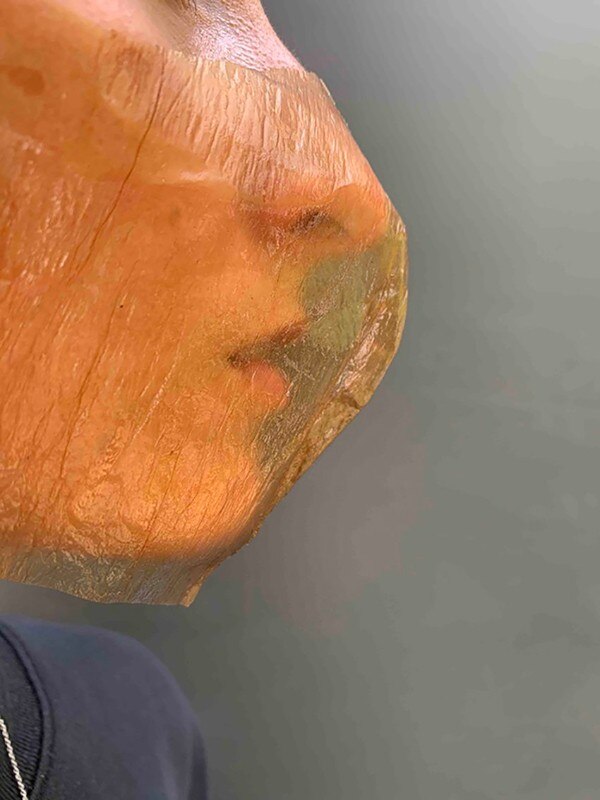

The concept of sustainability is radically implemented in the mask designed by the two bio-designers Elizabeth Bridges and Garrett Benisch of Sum Studio, which is the result of a study on certain materials, already present in nature, which could be the most suitable solution for filtering. The result is a mask based on bacterial cellulose sheets, which the two designers had grown directly in their kitchen during quarantine. Acetobacter xylinum only needs a little water, tea and sugar to multiply and generate, and within a couple of weeks a translucent membrane is formed, which once dried and treated proves to be as flexible and resistant as leather, large enough to cover a human face, and as filterable as an FFP2 mask.

Certified masks are those recognized as “filtering facepiece“ (FFP) by the European Union: FFP2 are able to filter at least 94% of airborne particles (FFP2); in the United States another classification is used, N95 (95% filtration efficiency). FFP3 and N99 masks filter much more, i.e. up to 99%. As I write this article, Paolo Colombo's Arya Mask (@aryaofficialstore) is also awaiting certification. He is an architect, founder of Atelier Archand, supporter of eco-friendly lifestyles; his mask aims at transforming "a technical, uncomfortable and impersonal object, into a renewed element able to change and interpret the personality, feelings and mood of the person wearing it", he tells Domus. The result is a mask composed of two semi-rigid shells between which an interchangeable filter is inserted, and 30 of them are included with each new one. Modular by choice and vocation, it can be customized by choosing the color of the elastic band that holds it on the face, or with stickers. Arya Mask was first digitally designed, “looking for the right compromise between the main operating elements and the ergonomic ones”, explains Colombo; then he moved on to prototyping, with seven main models; finally printing and testing on a sample of 10 people. The material used is called A-PET, “a precious raw material with extraordinary chemical, physical and mechanical properties“, transparent and easily disinfectable, “and with a recycling channel consolidated in every home”. Like many other masks that have been placed on the market in this period, Arya is the result of a conversion of a pre-existing production line: about forty out of 72 Atelier Archiand employees were involved in the process.

Arya and Reimiro - but we could also mention the Sicilian iMask or Warpmask (@warpmask), produced by Cifra, a company from Brianza specialized in anthleisure clothing - are just local examples of a global trend: to adapt existing design and production lines to the state of emergency, bringing heterogeneous skills and solutions that were unthinkable until very recently, triggering a process of differentiation and refinement in an object that has always been rather anonymous, a circular white filter attached with elastic bands to the face of those who had to wear it. The mask was first introduced as an anti-pandemic device for civil use by a Chinese doctor from Penang, Wu Lien-teh, called in Manchuria in the 10's of the last century, when the pneumonic plague used to kill with a mortality rate of 99%. The standard white mask is a direct subsidiary of the one proposed by Wu Lien-teh, who left precise instructions to the population on how to make one at home from a simple surgical gauze. So, if the use and consumption of masks has always been mainly concentrated in the Asian market, where it is normal to use them to protect oneself from pollution or flu, with China producing 10 million of them every day before the pandemic, today they are everywhere.

3M's experiments with nonwoven fabric date back to the 1950s, mainly carried out by a former editor of a furniture magazine, Sara Little Turnbull, who started with packet ribbons - made with a technique that transformed molten polymer into a fabric made of tiny fibers - and culminated in 1958 with a presentation of 100 potential product ideas to be realized. In charge of designing a shaped bra, Turnbull, who was often in the hospital visiting sick relatives in those years, proposed a "bubble-shaped" surgical mask, which 3M launched in 1961. The criteria for disposable respirators in the United States were defined in the following decade; the company's first N95 mask was approved in 1972. The technology behind the gift ribbons was transformed into a real filter. "Our respirator has evolved over the years in response to multiple needs, an evolution that will continue beyond the Covid-19 pandemic", says Paola Gualtieri, R&D Operational Leader, Product Stewardship & Sustainability SEE Region at 3M. The operation is optimized by years of experience: “When silica particles, iron powders, bacteria or viruses fly, they come across the fabric of synthetic fibers - which under the microscope look like a labyrinth - and they get trapped in this structure. In addition, 3M has electrostatically charged the material, so that even the smallest particles can be attracted and blocked by the fibers. The wearer will find it easier to breathe thanks to the grid between the fibers”. Special attention is paid to the design, adds Gualtieri, which allows the devices to adhere quickly, guaranteeing comfort and long hold. Since the beginning of the pandemic, the company has doubled its production of masks, with an estimated market release of about 1.1 billion, so nearly one hundred million every month. Furthermore, in collaboration with Ford, 3M has recently developed a new model of supplied-air respirator designed to protect workers' airways, with a rechargeable belt-mounted battery system that delivers filtered air to a special helmet, built using the components of the ventilated seats of the Ford F-150; 10 thousand units are already set to be distributed in the United States.

The door bells and it’s a bike messenger. It's the first one I've seen since the lockdown started and I find myself thinking that I would have expected more. He hands me an envelope with a U-Mask inside (@u.mask). The packaging is very well-kept, a semi-transparent anthrax-colored ziplock with a stylized U on it and an explanatory note. Inside, the outer part of the mask is made of a light fabric that makes it look like certain ultra-minimalist swimsuits and then the filter, a shell made of a porous and organic material that resembles cellulose. Only a few hours have passed since I spoke with Lorenzo Di Cataldo, marketing manager of U-Earth, a company that was born, he explains to me, from a line of research commissioned by the American army in order “to find solutions to possible chemical-bacteriological attacks“. Today, U-Earth is involved in the production of bioreactors for air decontamination, “we make clean air bubbles”, explains Di Cataldo, “with the aim of guaranteeing free access to clean air to everyone, just as for potable water”. The new U-Mask is the heir to a model launched five years ago, which employed the same biotechnology developed by the company against pollution; the current Model Two was created precisely as a result of the pandemic, with the intention of eliminating the waste created by disposable masks, and uses a filter made of innovative materials that provide a performance comparable to that of an FFP3 mask. “The filter is the result of our experience in the field of biological contamination“, says the marketing manager, “the real challenge was designing the cover and organizing the logistics”. For the cover they chose Econyl by Aquafil, a sustainable fabric made with regenerated nylon, while for the logistics “the main problem was the fact that we wanted to do everything in Italy as U-Earth does with bioreactors“. In the email conversation with Lorenzo, there are two particular ideas: a hope and a controversy. The controversy is against those who have improvised themselves as mask producers – “even relevant brands“ -, putting on the market “products that do not protect the consumer and those around him”, sending the price of nonwoven fabric skyrocketing and subtracting useful resources such as public funding: “it is very difficult to emerge for us who run a small company with innovative technology but without a budget for marketing and communication”. But his conclusion is full of optimism. “Our bioreactors were born to fight chemical-bacteriological wars, but they have proved to be excellent for fighting climate change, since everyone is a forest in a box”, Di Cataldo affirms, explaining that U-Earth's vision is that of a world where clean air is as standard as wi-fi in a hotel room. “And we hope that the awareness of the importance of clean air, devoid of viruses and bacteria, smog and other man-made pollutants, will lead increasingly more people to deal with the climate emergency”. Because even when the battle against the Coronavirus is over, the most serious threat to the survival of human beings on the planet remains the same, even if we have all talked about it less: the climate crisis.