Background

In May 2008, an earthquake measuring 8.0 on the Richter magnitude scale hit China's Sichuan province. More than 70,000 people lost their lives, and millions lost their homes. Ma'anqiao is one of the poorest villages in this quake-stricken area. Most of the village's houses—traditional rammed-earth courtyard dwellings—were severely damaged. Limited by a poor local economy and low levels of technology, villagers had difficulty in affording to rebuild their homes with conventional construction methods.

As this situation is very common throughout rural Southwestern China, a post-quake village rebuild demonstration project was launched in the village of Ma'anqiao by a university-based joint team. Supported by China's Ministry of Housing and Urban Rural Development (MOHURD), the initiative aims to convey an accessible, ecological, sustainable, healthy and humane way of rebuilding post-quake villages that local residents can afford, learn and pass on.

Tradition and challenges

The tradition of building with earth has been employed for thousands of years in the region where Ma'anqiao is located. Utilising local natural materials and traditional earth-based techniques, villagers are used to building houses themselves with the mutual assistance of relatives and neighbours. Nevertheless, the great damage caused by the earthquake made local villagers despair of their traditional earth-based dwellings. Building with concrete and bricks seemed the only reliable way to reconstruct their homes. However, due to transportation difficulties, it is impractical for villagers to source the quantity of industrial materials needed for their home construction efforts. Furthermore, the increased cost of manpower and materials after the earthquake became doubly unaffordable for villagers with their very low incomes.

In short, after the earthquake, not only did villagers see the total abandonment of their building tradition, but also a deep fracture in their original peaceful style of living. Faced with these post-quake challenges, villagers felt restless and confused about their reconstruction plan.

In response to these challenges, the most feasible and sustainable strategy for rebuilding villagers' homes and stimulating future development was not to build "for" them with outside resources, but rather to "empower" them to do so themselves with locally available resources and by tapping into their tradition of self- construction. This approach relies on a feasible technology that villagers can afford and easily manage for the self-construction of their homes.

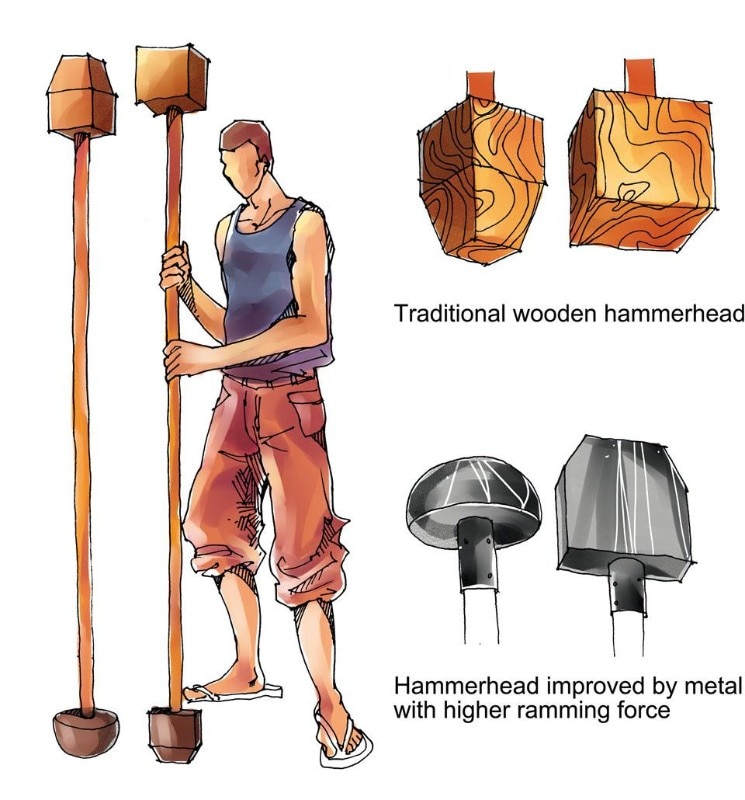

Field research of living with villagers for several weeks revealed that the local tradition of earth-based architecture would still be the most suitable solution if its disadvantages in a seismic performance could be overcome. Scientific studies and on-site experiments in the first phase led the team to develop a series of technical innovations in tools, materials and construction methods that can greatly enhance the earthquake resistance of traditional earth houses.

Field research of living with villagers for several weeks revealed that the local tradition of earth-based architecture would still be the most suitable solution if its disadvantages in a seismic performance could be overcome

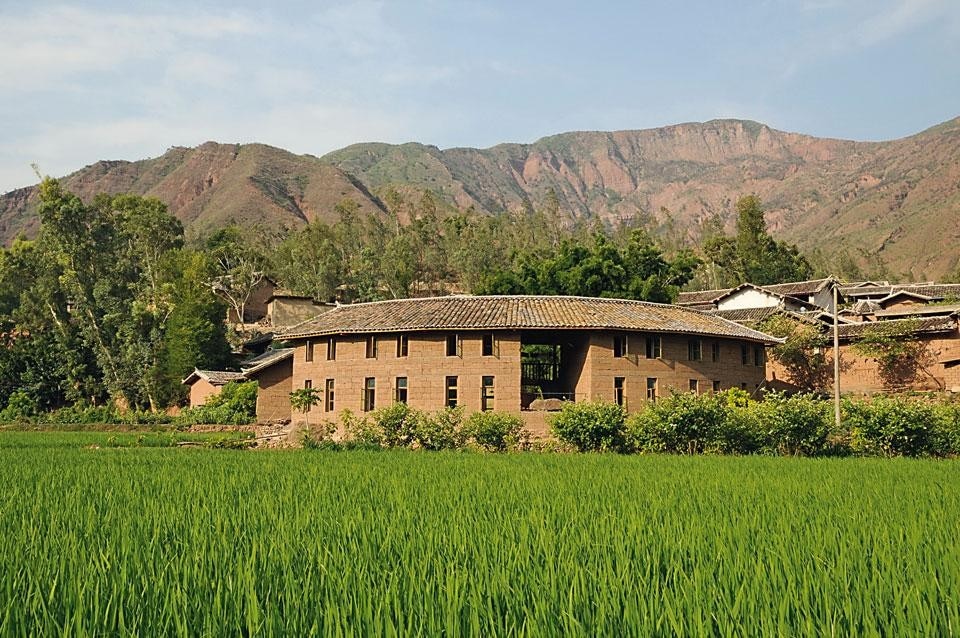

It was essential to give villagers a demonstration of how to rebuild with all the readily available resources. As a prototype, a new rammed-earth courtyard dwelling was constructed for an elderly couple in one month by the project team together with villagers mobilised from each family. Providing families with a participative training course on the basic techniques developed in previous studies, this hands-on approach allowed them to be convinced by the new construction and further understand how to rebuild their houses by themselves.

During construction of the prototype, the team fine-tuned all research products and construction experiences, condensing them into an easy-to-follow technical guide for villagers. Based on the traditional courtyard pattern with respect for local culture and lifestyles, the team also developed a number of design schemes that can greatly improve the living environment and be employed selectively in the reconstruction of houses according to individual conditions and demands.

Equipped with the guidelines, design schemes and especially the experiences gained from constructing the prototype, two months after the earthquake all 33 families had started to rebuild their own houses. To alleviate villagers' difficulties in removing demolition material, the team provided each family with several levels of financial support, encouraging them to rebuild on the original sites rather than occupy extra farmland. Throughout the reconstruction process, several members of the team lived with villagers to offer technical assistance. The construction of all village houses was completed by villagers themselves in just three months. With pleasant surprise, villagers poured their creativity and wisdom into their rebuilt homes. After all, they know best about their lives and demands.

A comprehensive evaluation has been conducted by monitoring the construction process and villagers' newly built houses over the past three years. The upgraded earth-based technology is easy to handle with simple tools so that each family's house could be rebuilt relying on just one or two employed craftsmen and free assistance from several neighbours.

At an average of only fifteen euros per square metre, the construction cost is one tenth that of new houses built locally with concrete and bricks. However, the price of building the courtyard dwelling complete with living and husbandry spaces can only be met with financial support to supplement family savings.

Over 90 per cent of materials are recycled from damaged buildings or sourced from natural products in the village. As well as having a far cooler and stable indoor ambience compared to concrete and brick houses, the new rammed-earth dwellings consume far less energy and have a minimal environmental impact throughout their lifecycle, resulting in a greatly enhanced ecological performance. Ultimately, the villagers' living needs were entirely satisfied by this healthier and more comfortable living environment.

The team also used the developed techniques to design and build a village centre to improve local public services. MOHURD has designated the centre and the whole village as a demonstration facility for training workshops open to villagers and craftsmen from regions with a tradition of earth-based construction. Ma'anqiao has once again found its original peace and harmony. The experiences and technical guidelines from the demonstration project have been published in a DIY construction manual, and have been further promoted by MOHURD in similar rural areas of Western China.

Jun Mu, Edward Ng, Tiegang Zhou, Li Wan, Professors at the Xi'an University of Architecture and Technology, Xi'an City, China, and the Chinese University of Hong Kong