The manufacture of “super black” carbon nanotube-based materials has traditionally required high temperatures, preventing their direct application to sensitive electronics or materials with relatively low melting points. This, along with poor adhesion, prevented their application to critical space and air-borne instrumentation.

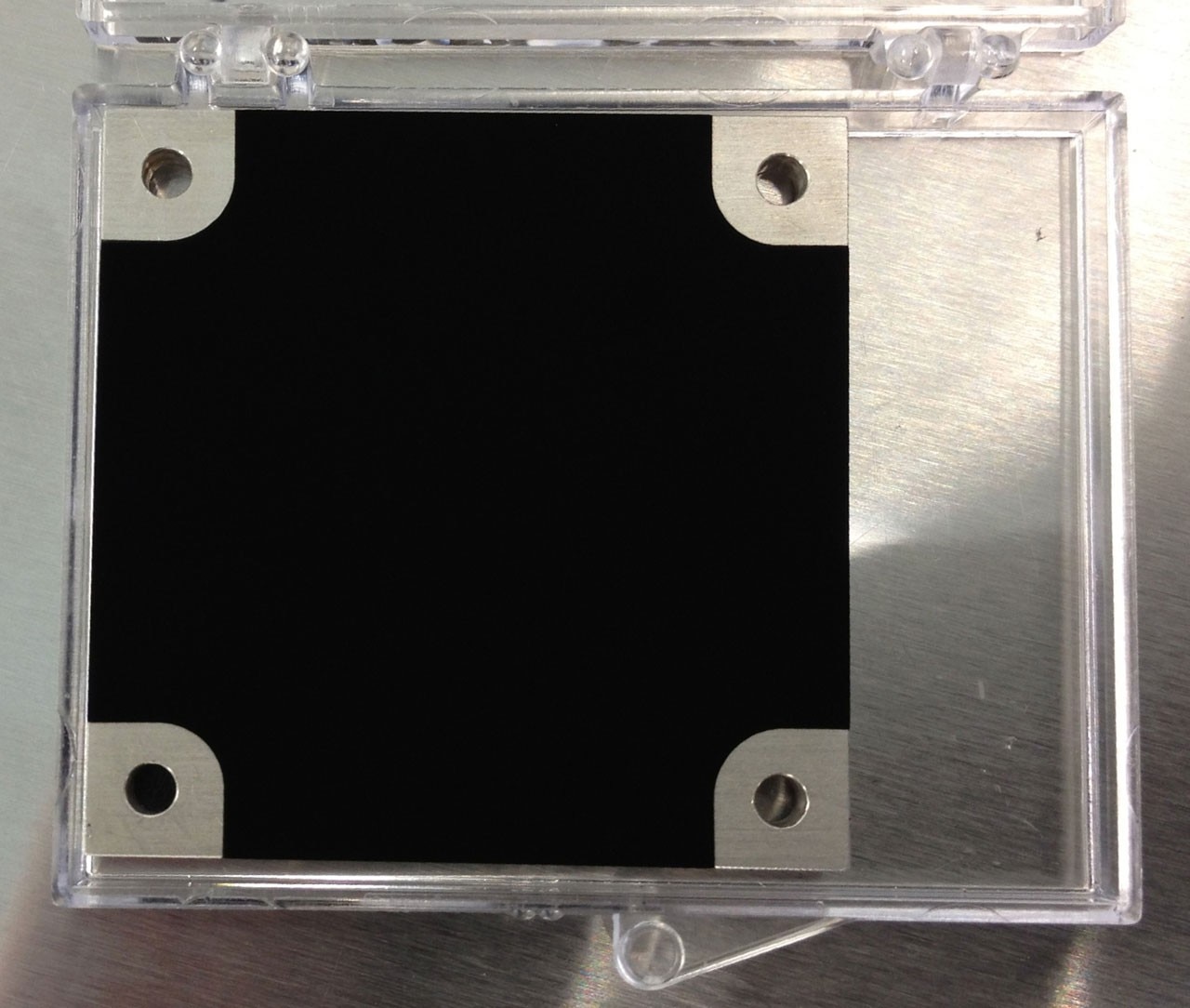

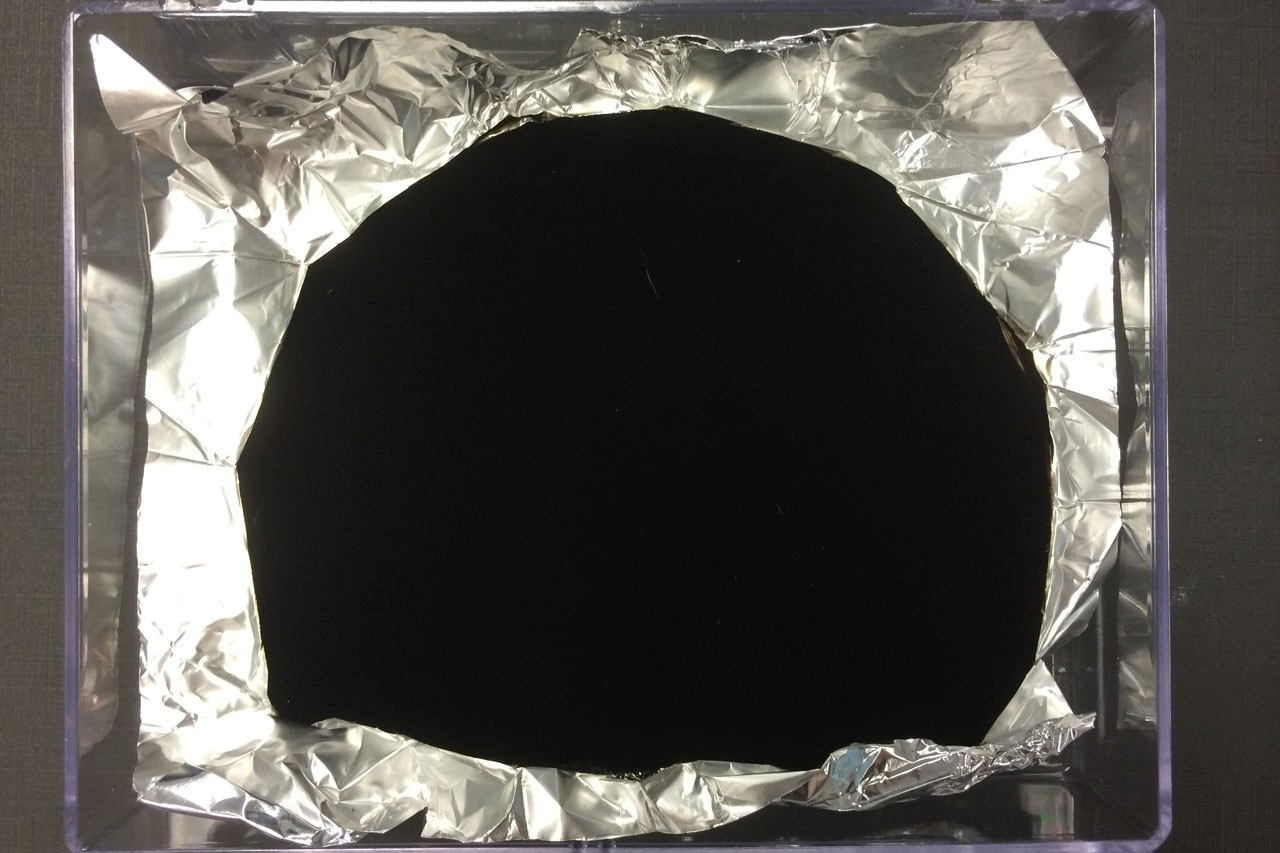

The two year development and test programme was completed in December 2013, during which period Surrey NanoSystems successfully transferred its low-temperature manufacturing process from silicon to aluminium structures and pyroelectric sensors. As part of the programme, qualification to European Cooperation on Space Standardisation (ECSS) standards was also achieved.

Vantablack®

Producer: Surrey NanoSystems